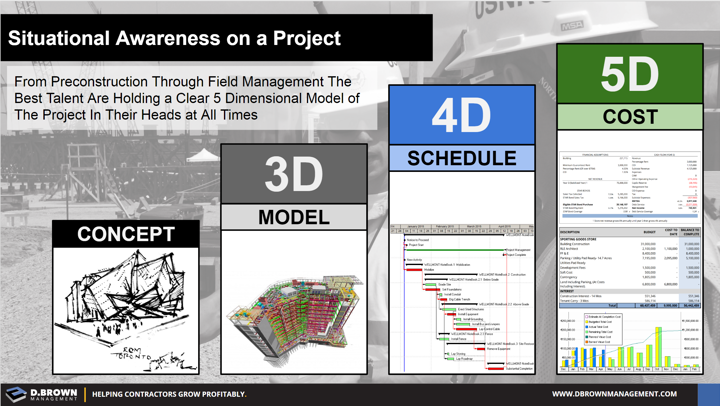

The best project team members have a complex 5-dimensional model of the project in their heads at all times.

They see not only the finished product in 3D but can take that model apart down to the individual components of each building system. They see the sequence and speed that each of those components must be put in place (4th dimension). They see the cost of each component and the different methods that can be used to put them in place (5th dimension).

BIM has the power to create a detailed 5D computer model and this technology is a huge help for project teams. It is however not a substitute for building “Situational Awareness” across the project team. This is what lean construction tools such as “Pull Planning” develop in teams.

Situational Awareness is something critical to survival training, military, construction projects, contracting businesses and life in general. The US Coast Guard has a great chapter in one of their training manuals on Situational Awareness.

Look up the “Two-Challenge Rule” on page 6 and ask yourself if that is applicable to having effective bid or project review meetings?