Except; of course for the first contractor on Mars!

Remember that Elon Musk came from a technical background where he was use to creating the future - things that did not exist yet. His first couple companies were all software with light requirements on capital, relatively small workforce, a single engineering discipline, little government regulation and fewer stakeholders.

As he is building Space-X and Tesla the complexity has been increased exponentially and he is having to learn to lead through that complexity. He has had to get use to that constant feeling of uncertainty and refine his skills leading a team even in the face of opposition, failures and many unknowns.

What construction leaders have in common with Elon Musk is that relative to the last few decades the industry is demanding changes at an exponential rate between technology, project delivery methods, talent shortages and industry consolidation.

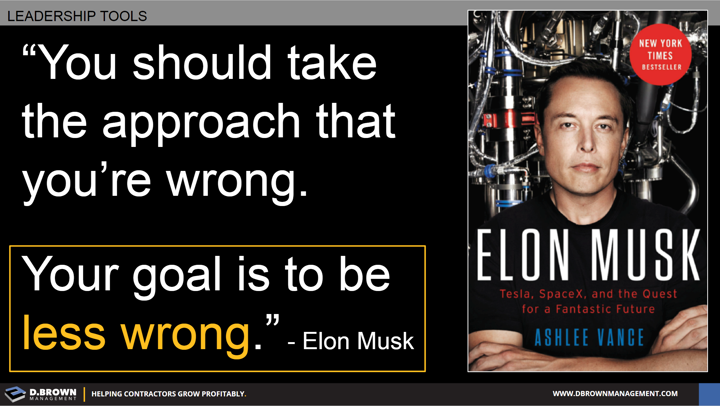

It’s worth learning how Elon Musk views the world and creates a vision for the future; especially how he deals with failure from an analysis and adjustment perspective.