Seek to fully understand that complex idea by learning each perspective while blending them together into your own model.

If an issue is complex then you WILL NOT be able to learn anything meaningful about it in the 99% of the media out there that is made up of 60 second clips and 200-500 word articles with the same basic info repeated over and over. If the issue is so simple that you could learn it in those short clips then it probably isn’t worth learning.

LEARNING IS HARD. If you want to learn something complex to the point where you can apply it then dedicate the time to do it.

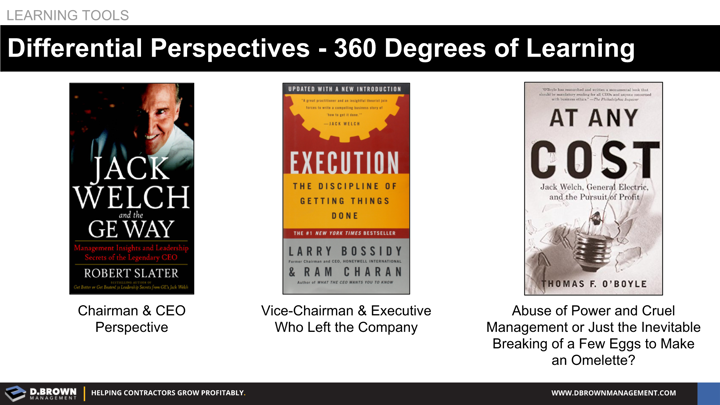

Just as an example let’s take the business practices and culture of General Electric from 1980-2000. They were very innovative with their talent management, business management, financial management and process improvement programs well before ‘lean’ was a term. There are a lot of lessons there that contractors and other businesses could apply today.

Pick up at least 3 different perspectives - often conflicting and read them all. Read with the intent to understand. Go out and talk to people at various levels that have first-hand or other relevant knowledge of the issue and hear all perspectives. It is only then that you can begin to form your own model and make great decisions.

What if more people took this approach to the many complex issues facing our businesses, our projects and our world?